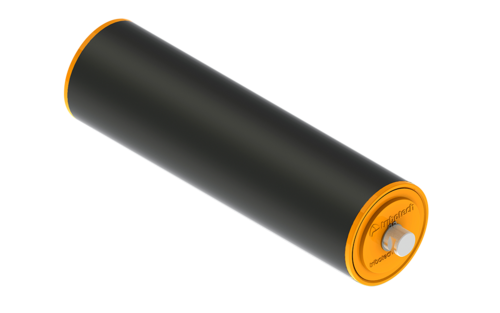

Benefits of a Tribotech Roller:

1. Belt Friendly.

When a conventional roller fails, the steel housings will turn into a ‘pizza cutter’, which will damage the belt and require immediate interruption to production.

Tribotech’s Composite Housing Technology is completely belt friendly and eliminate the risk of damage to the belt.

2. Extended Roller Life

Tribotech’s rollers are designed to maximise the achieved life through a low total indicator runout (T.I.R.), a heavy duty sealing arrangement and Tribotech’s unique composite housing technology.

3. Reduced Noise & Power Consumption

In addition to a longer achieved roller life, a low T.I.R. is also directly related to a lower noise emission and power consumption.

Our rollers can achieve up to < 60% Noise Emission when compared to conventional steel rollers.

4. Commercial Saving

Cost saving through reduced roller replacements, lower labour costs and reduced downtime.

Cross-Section of a Tribotech Roller:

1. Composite Housing

Tribotech’s composite housing technology is designed to withstand the heaviest load requirement comfortably, outperforming standard steel moulded housings by a wide margin. The housings allow for an even load distribution on the bearings, greatly improving the bearing life.

2. Rock-Shield

Our full-diameter rock-shields are stationary when the roller is in operation, which prevents premature failures caused by spillage and rock-jams.

3. Low-Friction Contact Seal

The Contact Seal is responsible for keeping any contaminants out of contact from the bearing while minimising the overall roller drag.

4. Greased For Life Ball Bearing

All Tribotech rollers are equipped with shielded, greased for life ball bearings from top tier bearing manufacturers.

5. Labyrinth Seal

The labyrinth seal is the first line of defence against dust and water ingression. It is designed to prevent water from entering the roller and pushing dust out by centrifugal force.

The conventional Steel Rollers are appreciated for their impact, load and wear resistance.

Tribotech's Steel Rollers are equipped with our unique polymer end-cap technology, which gives all the benefit of a conventional Steel Roller, while eliminating the risk of 'pizza-cutting', reducing noise and vibration, and improving bearing life.

Weartech is a high-quality composite roller that combines the best of both steel and plastic rollers, offering a roller life beyond conventional steel rollers while remaining belt-friendly, strong and lightweight.

5x Roller Life: Weartech Composite Rollers have proven to offer phenomenal wear resistance against the most abrasive applications, outlasting Steel Rollers by a factor of up to 5.

5x Load Capacity: Weartech is a high-load capacity roller, offering 5 to 6 times the strength of common Plastic Rollers made of PVC or HDPE and close to that of Steel Rollers. All Weartech Composite Rollers are machined for optimal roundness and low T.I.R., significantly increasing the life of the rollers.

40% Lighter: Weartech Composite Rollers are in average 40% lighter than equivalent Steel Rollers. This not only reduces safety risks, bit also improves roller installation productivity.

| Material | Weartech | Steel Roller | PVC Roller | HDPE Roller |

|---|---|---|---|---|

| Roller Strength |

|

|

poor | poor |

| Roller Life |

|

good | poor | poor |

| Wear Resistance |

|

good | poor | fair |

| UV Resistance & Maximum Operating Temperature |

|

|

poor | good |

| Belt Friendly |

|

poor |

|

|

| Weight & Noise |

|

poor |

|

|

| Corrosion Resistance |

|

poor |

|

|

- Excellent

- Good

- Fair

- Poor

Weartech+ For extremely harsh environments, Tribotech also offer Weartech+ Composite Rollers, with even greater wear properties.

Impact Rollers are too often the cause of unnecessary downtime. It is important to have the right Impact Rollers to achieve the longest life. Our Impact Rollers are manufactured with premium quality rubber rings, removing the risk of having rubber rings breaking.

Tribotech offer a wide range of Impact Rollers designed for the toughest applications.

Tribotech manufacture a wide range of Weigh Quality Rollers machined to a T.I.R. (Total Indicator Runout) of 0.1mm and balanced to ISO1940.1 G16.

Our Weigh Rollers are manufactured using our Weartech Composite shell, which eliminates carryback and reduces wear, therefore increasing the time of which the roller stays balanced.

Roller Order Form

Complete the Order Form on the right and one of our Tribotech team members will be in touch within 1 working day.

Shaft Type 1 – Slot

Shaft Type 2 – Open Slot

Shaft Type 3 – Hole